Activated carbon has a wide range of applications in many industries. Depending on the application, it can be used in a number of different ways. Further information on this lightweight, special material, including some of its benefits of activated carbon and uses, is provided below.

What is Activated Carbon?

Adsorbents like activated carbon are good at luring contaminants and trapping them inside themselves. Because of its porous structure, large surface area, and high surface reactivity, it can accomplish this.

Since it is simple to get and can be made from a basic material like wood, coal, or coconut shells, activated carbon is a very cost-effective option for several businesses. Although each base material could give a somewhat different result, they all typically perform the same functions in various applications.

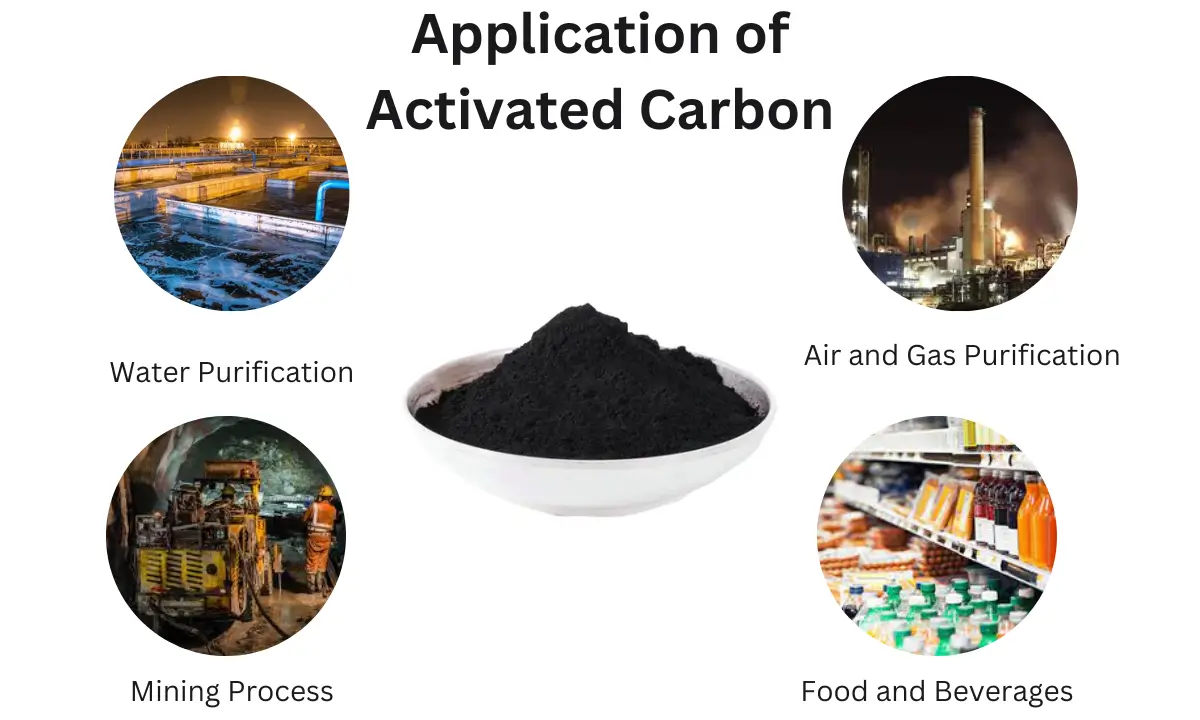

Applications of Activated Carbon

There are a lot of applications for activated carbon. A specific type of activated carbon is used depending on the application. Hence, it's important to choose the correct grade and size while considering the pollutant you want to remove or the level of purity you want to reach.

There are numerous uses for activated carbon, including the storage of methane and hydrogen, air purification, capacitive deionization, medical treatment, sewage treatment, compressed air filters, teeth whitening, super capacitive swing adsorption, solvent recovery, decaffeination, gold purification, metal extraction, water purification, hydrogen chloride production, edible electronics, and many others.

These are a few of the main applications of activated carbon.

Air and Gas

To filter gasses, many types of activated carbon can be used. Cloth, pelletized, and granular activated carbon are examples of the specific forms that can be used depending on the desired results. Applications for activated carbon in gas purification include filtering breathing air in air conditioners and eliminating hydrogen sulfide from natural gas. In this second use, activated carbon aids in purging the recirculated air of radon and smells.

Mining

Moreover, gold recovery from mining uses activated carbon to recover precious metals. In the latter phases of mining, activated carbon is used to separate carbon from cyanide due to its adsorption properties.

Food and Drinks

In the food and beverage industry, activated carbon is used to enhance the flavor, smell, and purity of a variety of foods and beverages, including concentrated juice. Activated carbon can be used to decolorize sweeteners and remove undesirable by-products from them.

Treatment of Water

Both primary and tertiary treatments for water filtration include activated carbon. Granular and powdered activated carbon are both used to purify water. The primary goal of the first treatment is to eliminate and retain large particles. Activated carbon is used to reduce taste and odor in the last stages of water treatment.

Types of Activated Carbon

Activated carbon comes in a variety of forms. These are the primary types of activated carbon you may encounter; each is more appropriate for a certain purpose than another.

Granular Activated Carbon

Due to its somewhat larger particle size, granular activated carbon has a smaller exterior surface than powdered activated carbon. This kind is mostly used for water treatment, air treatment, and general deodorization.

Pelletized Activated Carbon

This consists of pellet-shaped mixtures of powdered activated carbon and a binder. The pellets have a low dust content, strong mechanical strength, and a low-pressure drop, which makes them generally used in gas phase applications.

Coconut Shell-Based Activated Carbon

These coconut shell carbons are best suited for use in point-of-use water filters, respirators, and critical air applications because of their extremely large interior surface areas, microporosity, high hardness, and low dust content.

Benefits of Activated Shell-Activated Carbon

Extremely high surface area with a high percentage of micropores

High toughness and less production of dust

Excellent purity, with the majority of items having an ash percentage of no more than 3-5%

Green and renewable raw materials

Powdered Activated Carbon

It is often added directly to processing equipment, including raw water intakes, gravity filters, and clarifiers, since it is a fine type of activated carbon. It is rarely used in a specialized vessel because of the potential head loss that might occur.

Coal-Based Activated Carbon

This reasonably inexpensive filter medium is frequently in great demand for both liquid and gas applications. The large surface area of coal-based activated carbon is characterized by mesopores and micropores.

Benefits of Coal-Based Activated Carbon

Uniform density

Hard materials that produce less dust.

Economical

Impregnated Activated Carbon

Activated carbon in this form has been impregnated with inorganic substances like silver and iodine. The largest use of impregnated activated carbon is the filtration of drinking water for home use.

Wood-Based Activated Carbon

In industrial applications of activated carbon that are generally served by coal or coconut products, they provide different performance characteristics. Due to its distinctive porosimetry, wood-based activated carbon has a large surface area with both mesopores and micropores and outstanding decolorizing characteristics.

Benefits of Wood-Based Activated Carbon

Relatively low density

Sustainable raw material source

Catalytic Activated Carbon

Surface-modified activated carbon is another name for this fifth variety of activated carbon. It may begin and intensify chemical reactions in addition to being adsorptive, which makes it effective in eliminating pollutants from drinking water.

Adsorption in Activated Carbon

Adsorption is the process by which gaseous substances or solutes that have been dissolved in liquids accumulate on the surface of solids. Adsorption is mostly a physical process, meaning that compounds that are deposited on a solid do not interact chemically with the adsorbent. The material to be adsorbed from the liquid or gas phase is referred to as an adsorbate, or solutes dissolved in liquids, onto the surface of solids.

The adsorbing solid is known as an adsorbent. Adsorption is mostly a physical process, meaning that compounds that are deposited on a solid do not interact chemically with the adsorbent. The material to be adsorbed from the liquid or gas phase is referred to as an adsorbate, whereas the adsorbing solid is known as an adsorbent.

Factors Influencing Adsorption

In addition to the characteristics of the substances to be eliminated, other factors to consider include molecular size, hydrophilic behavior, and polarity. Adsorbent features, such as the amount of inner surface area, pore structure, chemical properties, and other physical and chemical variables, are the main determinants of adsorption.

The solute adsorbate concentration, temperature, the make-up of the solution or gas mixture, the pH level of the solution during the liquid phase of adsorption, and relative humidity during the gas phase of adsorption are additional parameters.

The Benefits of Activated Carbon in Water Treatment

Activated carbon has a number of advantages over other substitutes when it comes to purifying water. The use of activated carbon in water treatment has the following four main benefits of activated carbon.

Removal of Contaminants

As previously discussed, activated charcoal draws and holds onto impurities. Its adsorptive properties allow it to efficiently remove a wide range of impurities from the water, including those of diverse types and sizes.

Regulating Flavor and Odor

The flavor of water can be noticeably improved when the appropriate sort of activated charcoal is used. Activated carbon may successfully reduce odors as well.

Solid Adsorbent

Because of its capacity to absorb more than one or two impurities, activated carbon is widely used in the water purification process. This makes it efficient and cost-effective to utilize attributes that any water purification facility would value for the reduction of overhead and improvement of product quality.

Reliable and Efficient

Activated carbon is very reliable and effective. When the right form is used, there is a very minimal risk of failure as long as all pertinent factors are taken into account. It is a tried-and-true system that has advanced through time to become the industry standard for water filtration.

JMB Chemicals is a leading activated carbon manufacturer in Gujarat that supplies high-quality activated carbon to provide the appropriate standard for each application. JMB Chemicals are also granular activated carbon suppliers who also supply washed activated carbon, unwashed activated carbon, and coconut shell-based activated carbon. Get a quote from us here.